Deposition Date

2025-05-23

Release Date

2025-11-12

Last Version Date

2025-11-12

Entry Detail

PDB ID:

9V4B

Keywords:

Title:

Selective Production of Versatile L-Glyceraldehyde from C1 and/or C2 aldehydes

Biological Source:

Source Organism(s):

Aeromonas sp. ASNIH1 (Taxon ID: 1636606)

Expression System(s):

Method Details:

Experimental Method:

Resolution:

2.10 Å

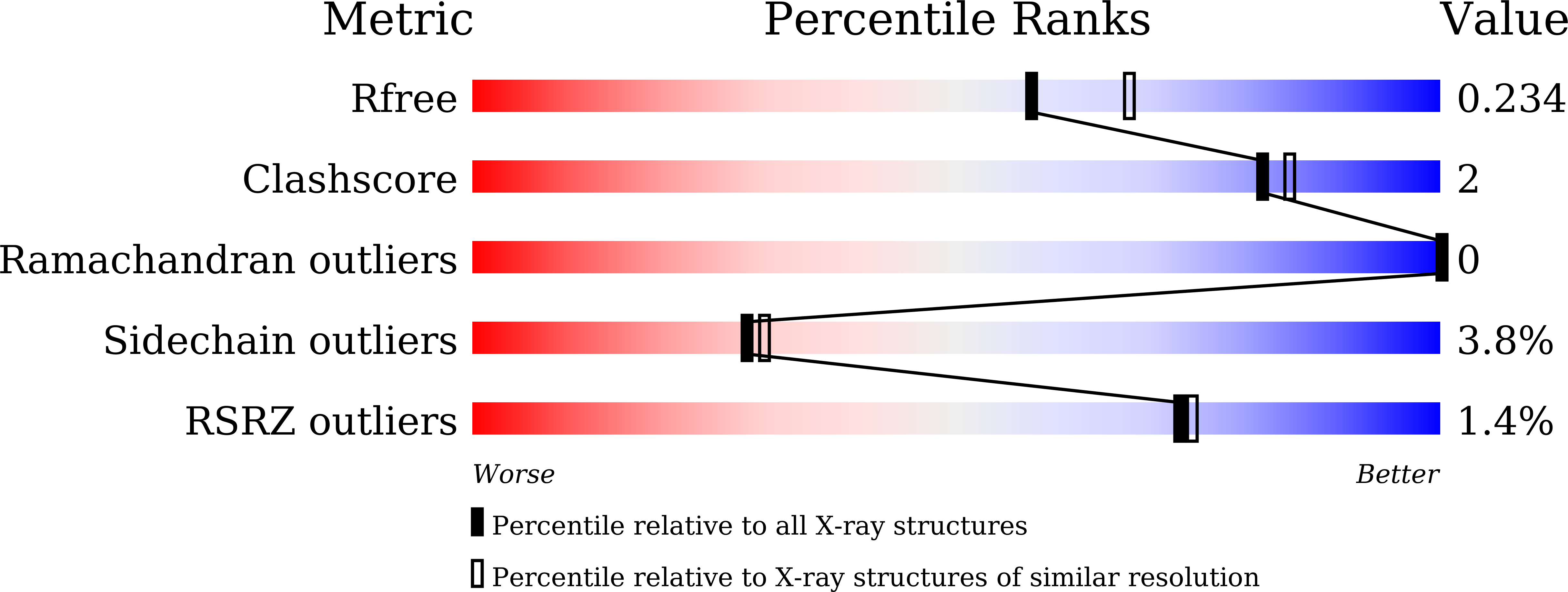

R-Value Free:

0.22

R-Value Work:

0.20

R-Value Observed:

0.20

Space Group:

C 2 2 21