Deposition Date

2019-04-23

Release Date

2019-11-20

Last Version Date

2024-11-20

Entry Detail

PDB ID:

6JXG

Keywords:

Title:

Crystasl Structure of Beta-glucosidase D2-BGL from Chaetomella Raphigera

Biological Source:

Source Organism(s):

Chaetomella raphigera (Taxon ID: 241714)

Expression System(s):

Method Details:

Experimental Method:

Resolution:

1.90 Å

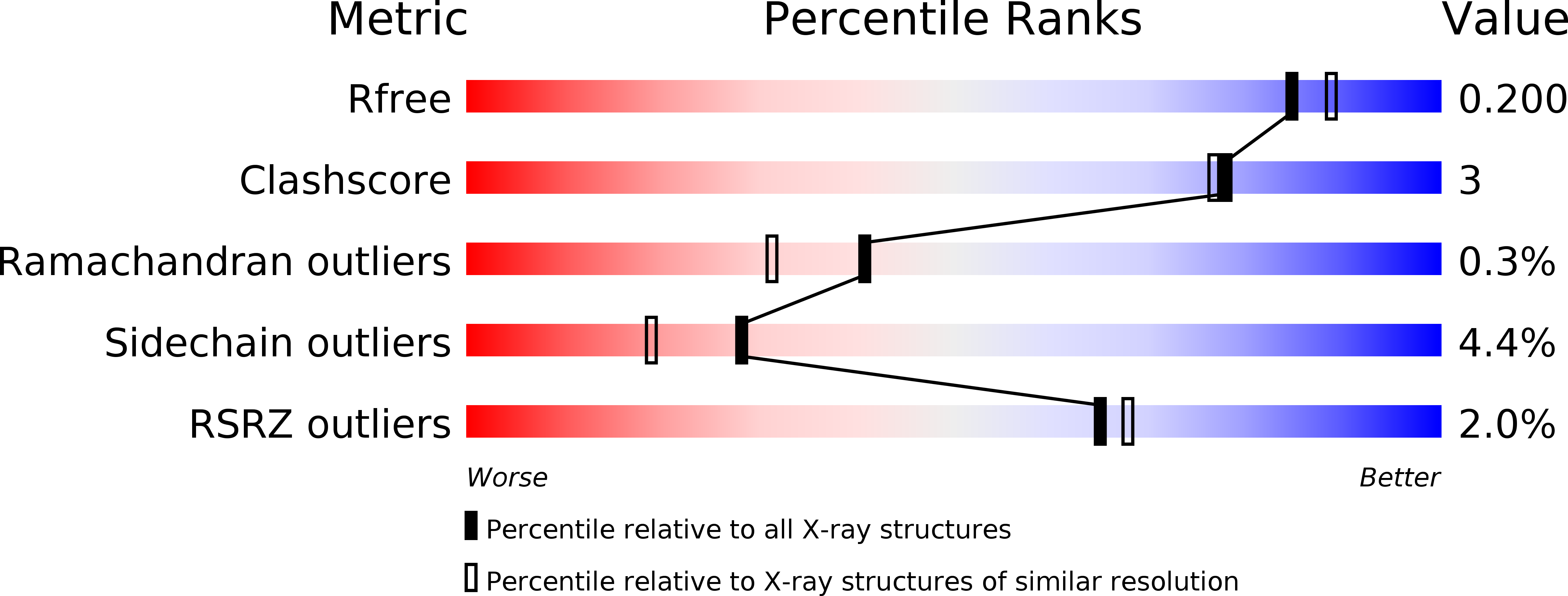

R-Value Free:

0.19

R-Value Work:

0.14

R-Value Observed:

0.14

Space Group:

P 21 21 21